Introduction to The Basic Components of Wooden Furniture and Their Functions

May 26,2025

May 26,2025

Topmax Furniture

Topmax Furniture

The basic components of wooden furniture or the wooden structure of furniture mainly include square timber, board, wooden frame and box frame. In the use of furniture, the overall life often depends on the node connection performance of the basic components. The reason for the damage of furniture or connection is often not because the load exceeds the maximum damage limit of the design, but more importantly, the loosening of the connection part of the component under the interaction of fatigue and creep, which leads to fatigue damage. Therefore, in the structural design, the Wooden Furniture Factory should select suitable component forms and appropriate joint methods for interconnection according to the different types and needs of furniture.

Square timber

Square timber is the simplest component of wooden furniture. It generally refers to long furniture parts with a width and thickness size that are close (the width and thickness size ratio of the rectangular section is less than 2), and the length is always many times longer than its cross-sectional size. In the use of square timber in large furniture parts, small square timbers are often glued in the width, length, thickness and other directions to meet the product size requirements.

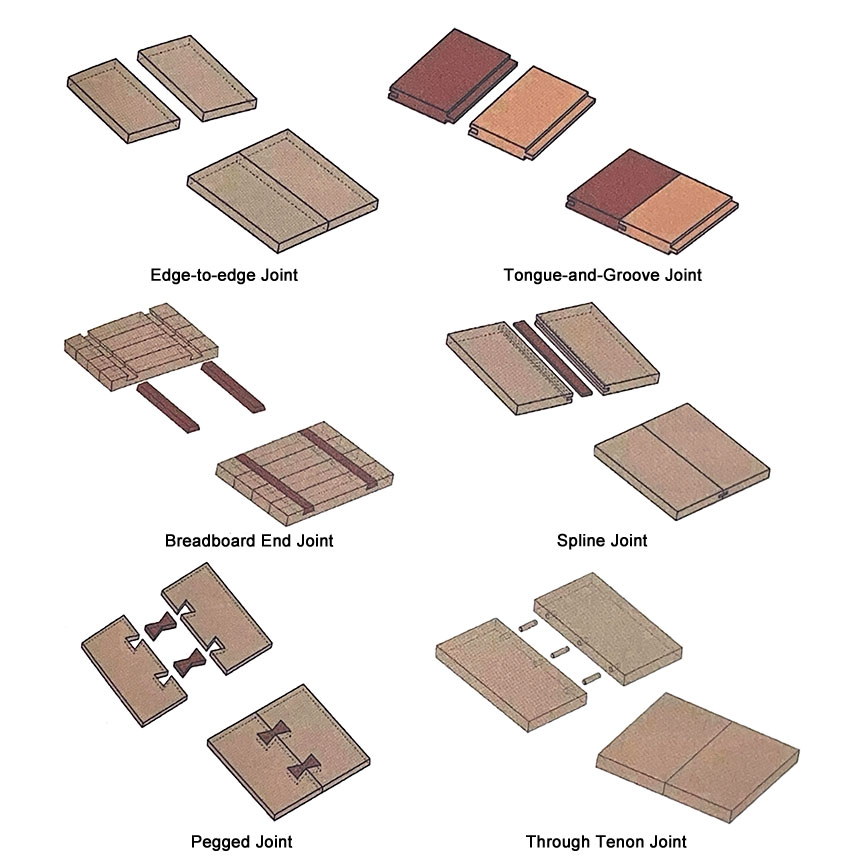

Gluing on width, Wooden Furniture Factory is mainly used to manufacture wide-width parts such as tabletops, chair seats, door panels, etc., which can be achieved by flat or mortise and tenon jointing. The joint surface of flat jointing should be planed flat and straight, and the joints of adjacent narrow boards should be tight and seamless. Adhesives are used for glue pressing. The structure is simple to process and the production efficiency is high. It is mainly used for rough materials with small length and flat board surface, such as chair surface glue. Groove joint is suitable for long material glue joint. During processing, the plane must be processed as the reference surface first, and then the side must be milled to process the grooves and tenons with concave and convex structures, and then glued and spliced. This kind of structure is easy to align and has high strength. Commonly used adhesives are animal glue, polyvinyl acetate emulsion glue, urea-formaldehyde resin glue, etc.

Gluing on length is often used to manufacture structural and non-structural materials such as wooden doors, windows, furniture and building decoration parts, which can be achieved by butt joint, bevel joint, finger joint and other methods. Butt joint is the joint of the end faces of wood, with low strength, and is often used in the processing of various cladding core boards. Bevel jointing is to change the plane of the flat joint into a bevel, and use adhesive and pressure bonding. The processing is relatively simple and the production efficiency is high, but the joint surface should not be aligned during gluing, which easily produces surface unevenness. Finger jointing is to process more than two tooth shapes at the joint of the solid wood narrow board before the board is assembled, and use adhesive and pressure bonding. The surface of the board is flat and the joint strength is high, but the processing is relatively complicated. In addition, the wood for finger jointing should be selected from the same tree species or tree species with similar material properties and density as much as possible, and the moisture content of the mixed wood should be consistent.

The thickness gluing mainly adopts plane gluing, and the joints on the length of each layer of board should be staggered during processing.

Boards

According to the different materials and structures, wooden boards mainly include four forms: whole board, plain board, covering board, and frame inlay board.

Whole board is often used to manufacture door panels, panels and chair seats of various furniture. It can be realized by flat jointing, tongue-and-groove folding, through-strip jointing, and insertion tenon jointing. During the processing, Wooden Furniture Factory should control the narrow board width of the board within 200mm to reduce the shrinkage and warping of the board.

Plain board refers to the board-like components that are directly cut from the wood-based panels such as plywood, fiberboard, and creative board without veneer treatment, and are veneered or painted and edge-sealed according to the needs of the surface decoration of the furniture products.

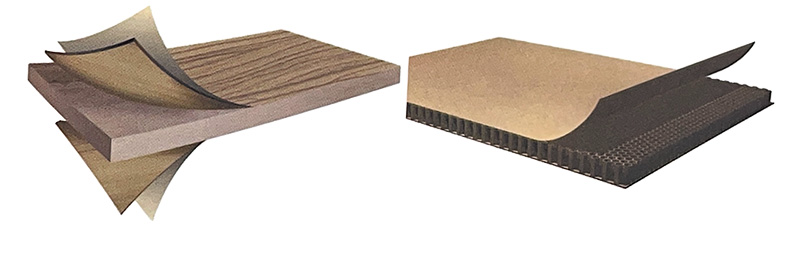

Overlay board is a board-like component with the required width made by pressing the veneer material and the core board with glue. Commonly used overlay boards mainly include solid boards made of plywood, fiberboard, and particleboard as the base material, and then glued with veneer materials, or hollow boards made of wooden frames or wooden frames with various hollow fillers, and veneer materials pasted with single-sided or double-sided adhesive. The board surface is flat, rich and beautiful, and has a decorative effect.

Frame inlay refers to a board formed by various shaped thin boards, panels, etc. embedded in the wooden frame by cutting or notching in the middle of the wooden frame. The cut-out panel is made by making a shovel in the wooden frame, and then inserting thin boards and panels into the shovel, and adding various linear strips. The structure is simple to assemble and the panels are easy to replace after being damaged. The grooved panel is made by directly cutting a groove on the inside of the wooden frame, and inserting the panels while assembling the frame. The structure is firmly embedded, but the replacement of the panels will damage the wooden frame structure and is not easy to disassemble. In addition, when embedding various mirrors and glasses in the wooden frame, it is necessary to use strips with various cross-section shapes to press around the glass or mirror, and then fasten it to the wooden frame with wood screws.

Wooden frame

The wooden frame is usually made of a series of square materials connected vertically and horizontally in the form of mortise and tenon joints. It is often used to manufacture furniture components such as door frames, window frames, mirror frames, frames, and tripods. Depending on the purpose of the wooden frame, horizontal and vertical materials can be added in the middle of the frame during design, namely horizontal bars (horizontal braces) and vertical bars (vertical braces).

According to the cross-sectional dimensions of the square material, the position of the components in the furniture, the bonding strength, the aesthetics and other requirements, the wooden frame corner joints can adopt various joint forms.

Box frame

The box frame is a frame composed of four or more boards. Commonly used joint methods include dovetail joints, right-angle joints, nail joints, etc.

Inquire Now

Inquire Now

Home

Home Innovation Strategies Adopted In Modern Furniture Design

Innovation Strategies Adopted In Modern Furniture Design  You May Also Like

You May Also Like

Tel

Tel  Email

Email  ADDRESS

ADDRESS