Wooden Furniture Joinery Methods

May 23,2025

May 23,2025

Topmax Furniture

Topmax Furniture

Each wooden part, component and other member of wooden furniture needs to be connected to form a finished product. The connection between parts is called joint, which is an important part of furniture structure. Generally speaking, wooden furniture manufacturer believe that the following are the commonly used joint methods for wooden furniture.

Mortise and tenon joint

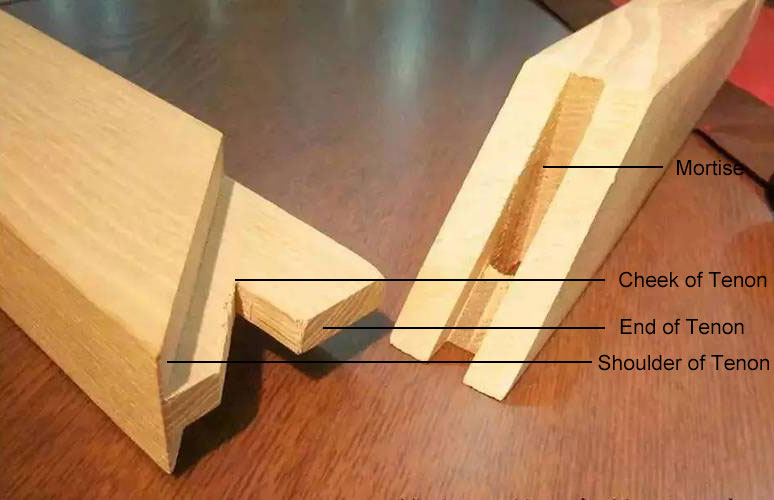

Tense and tenon joint is the most common joint method of frame structure, similar to the wooden frame beam-column structure in ancient Chinese architecture, with clear and reasonable load transfer. Mortise and tenon joint is a concave-convex joint method used on two wooden components. The protruding part is called tenon or mortise, and the concave part is called mortise or mortise, mortise groove, and the names of its parts are shown in the figure.

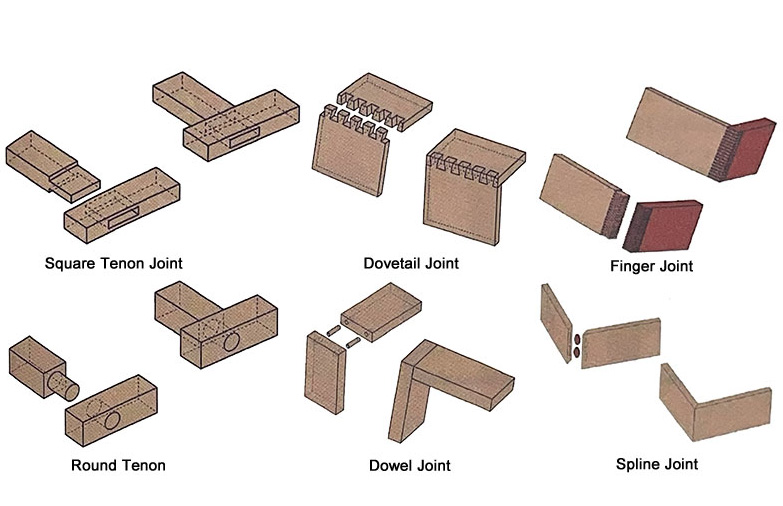

The most basic form of mortise and tenon joint is to insert a tenon into the mortise of the corresponding part, while the complex form is a group of mortise and tenon joints that are indistinguishable in multiple directions. There are many types, as shown below.

According to the different basic shapes of the tenon, it can be divided into right-angle tenon, dovetail tenon, finger tenon, round tenon, round bar tenon, sheet tenon, etc.

According to the number of tenons, it can be divided into single tenon, double tenon and multiple tenons. In the manufacture of wooden furniture, as the number of tenons increases, the gluing area of the tenon increases, which improves the overall strength of the wooden products. Generally, the square materials in the wooden frame are mostly joined by single tenons and double tenons, such as tables and chairs; the box frame is mostly joined by multiple tenons, such as wooden boxes and drawers.

According to the relationship between the tenon and the workpiece itself, it can be divided into integral tenons and inserted tenons. The integral tenon is directly processed at the end of the wooden part, and there is no separation between it and the square material, such as right-angle tenon and dovetail tenon; the inserted tenon is a single part that is processed separately and inserted into the processed part, such as round bar tenon and tenon piece.

According to the depth of the mortise, it can be divided into hidden tenons and visible tenons. The rear end of the hidden tenon joint is not exposed, also known as a non-through tenon (generally, wooden furniture manufacturer adopt this type of joint, especially in the external structure), which can avoid the tenon end from being exposed and increase the aesthetics of the product, but due to the small joint surface, the joint strength is worse than that of the exposed tenon; after the exposed tenon joint, the tenon head passes through the mortise, and the tenon end is exposed, also known as a through tenon, with high joint strength and a large joint surface, but the tenon end is exposed, affecting the aesthetics.

According to whether the side of the tenon is exposed or not, it can be divided into three types: open tenon, semi-open tenon and closed tenon. After the open tenon joint, the entire side of the tenon can be seen, which is easy to process, but has poor strength and affects the aesthetics. It is mostly used for the joint between the upright and the cap head of window sashes and door sashes; after the semi-open tenon joint, part of the side of the tenon can be seen, which can prevent the lateral movement of the tenon, increase the gluing area, and improve the joint strength. It is mostly used in parts of furniture structures that do not require too high requirements; after the closed tenon joint, the side of the tenon cannot be seen, the joint strength is high, the appearance is better, but sometimes it is easy to rotate sideways.

Nail joining

Nail joining generally refers to the process where wooden furniture supplier directly join two parts together with nails. It has the characteristics of simple process and high production efficiency, but the joining strength is relatively low, which affects the appearance. It is generally only suitable for the joints inside the furniture, the parts that are not exposed on the surface, and the places where the appearance requirements are not high. In the process of furniture connection and assembly, wooden furniture supplier use relatively many types of nails, including metal, bamboo, and wood. Bamboo and wooden nails are more commonly used in traditional Chinese furniture. As shown in the figure, in the wedge nail tenon structure of the round chair, the arc material is cut and the upper and lower pieces are used to join the tenons, and then a parallelogram wedge nail is inserted in the middle, which can prevent the connection materials from shifting up and down and left and right, so that they are tightly joined and connected into a solid and firm whole. Metal nails are most commonly used in modern furniture, including round steel nails, flat head round steel nails, saddle nails, fishtail nails, etc.

Wood screw joining

Wood screw joining is to use a wood screw to pass through the screw hole of one joined part and screw it into the other joined part to firmly connect the two. Wood screw joints have the advantages of simple process and low cost, but they cannot be used for multiple disassembly and assembly, otherwise the bonding strength will be affected. Wood screws exposed on the surface of furniture will affect the appearance. They are generally used to fix furniture panels, cabinet panels, back panels, cabinet top panels, chair seats, tripods and other parts, and to install various connectors and accessories such as handles, door locks, and drawers. The types of wood screws include flat heads, cross heads, hexagon heads, etc., and the end forms include flat heads and semi-circular heads. They can be assembled with manual or electric tools. The holes of the fasteners can be pre-drilled, and a loose fit is used between the wood screws.

Glue joint

Glue joint refers to the method of using adhesive alone to glue the main materials or components of furniture to make parts and the entire product. It helps to make small materials into big uses, short materials into long uses, and inferior materials into good uses. It not only saves wood and stabilizes the structure, but also improves and improves the decorative quality of furniture. In recent years, with the continuous development of science and technology, the types of glue used by wooden furniture manufacturer have been continuously updated. Urea resin glue (UF) is a synthetic resin adhesive with a large amount of use in the wood industry. It is generally used in the production of wood products and wood-based panels, as well as wood gluing, veneer lamination, thin wood veneer, etc. It has low cost and simple operation, but it shrinks greatly during curing, and the glue layer is brittle and easy to age; phenolic resin glue (PF) is made by the condensation of phenols and formaldehyde. It is mainly used for the impregnation of paper or veneer, the manufacture of laminated wood and water-resistant wood-based panels, with high cost, easy cracking, long curing time and high curing temperature; resorcinol resin glue (RF) is mainly used for special wood panels, building wood structures, bonding curved components, Bonding of finger-jointed or integrated wood products; melamine resin glue (MF) is mainly used for resin-impregnated paper, resin paper laminates, and artificial board veneers; polyvinyl acetate emulsion glue (PVAc), also known as milky white glue, is widely used in the wood products industry, such as jointing, board splicing, decorative veneer, etc., but has poor water resistance, moisture resistance, and heat resistance; hot melt resin glue is mainly used for veneer splicing, veneer splicing, board decorative veneer, board edge banding, mortise and tenon joints, V-groove folding gluing, etc.; polyurethane resin adhesives are widely used in the manufacture of wood-based panels, veneer laminates, finger-joined integrated wood, various composite boards and surface decorative boards, as well as the bonding of PVC, ABS, rubber, plastic, and leather.

Connector bonding

Connectors are a special component that can be disassembled and assembled multiple times. They are also an indispensable type of furniture accessories for modern detachable furniture. They can be made of metal, plastic, nylon, plexiglass, wood, and other materials. According to the role of furniture hardware on furniture, it can be divided into structural hardware, decorative hardware and functional hardware. Decorative hardware refers to hardware installed on the outer surface of furniture for decoration and embellishment, and is an integral part of the furniture morphological elements; structural hardware refers to hardware that connects the skeleton structure of panel furniture to realize the use function of panel furniture and plays a structural support role, including connecting structural hardware, supporting structural hardware, flip structural hardware, push-pull structural hardware, dragging structural hardware, folding structural hardware, lifting structural hardware, rotating structural hardware, hanging structural hardware, etc.; functional hardware refers to hardware that is dedicated to furniture space expansion and application, or auxiliary function expansion and derivation in furniture use, except for decoration and connection, including storage function hardware, adjustment function hardware, protection function hardware, safety function hardware and hidden function hardware.

Connector connection is widely used in disassembly and assembly furniture and panel furniture, which can simplify product structure and production process, is conducive to product standardization and generalization of components, facilitates industrial production, and also provides great convenience for product packaging, transportation and storage. For example, the detachable leisure table shown in the figure below mainly consists of three parts: a table frame, table legs and table top. The table frame and table legs are connected to each other by plug-in, bolts and nuts; the table top and table frame are connected by mounting grooves. The mounting grooves are stamped and installed on the upper inner side of the table frame, tightly fitting with the clips on the convex edge of the lower end of the table top, making the product lighter, more flexible and less prone to deformation.

Inquire Now

Inquire Now

Home

Home Introduction to The Basic Components of Wooden Furniture and Their Functions

Introduction to The Basic Components of Wooden Furniture and Their Functions  You May Also Like

You May Also Like

Tel

Tel  Email

Email  ADDRESS

ADDRESS